BGA Chip Reballing

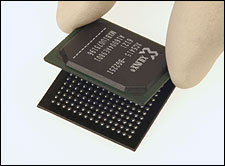

BGA need to reballed for a variety of reasons. Almost all reballing falls in to the following categories:

- The device was pulled off a PCB and needs to be placed back on the board

- The device is not available in the right alloy-and the ball need to be changed out

- The device needs to be reablled so a failure analysis can be performed on the part

There are numerous methods one can use to reball a BGA chip. The method depends on the volume of the rework, the type of package and the alloy being placed on to the device.

There a variety of methods one can use for low volume reballing requirements (less than a few hundred pieces). One can use the following methods for BGA chip reballing:

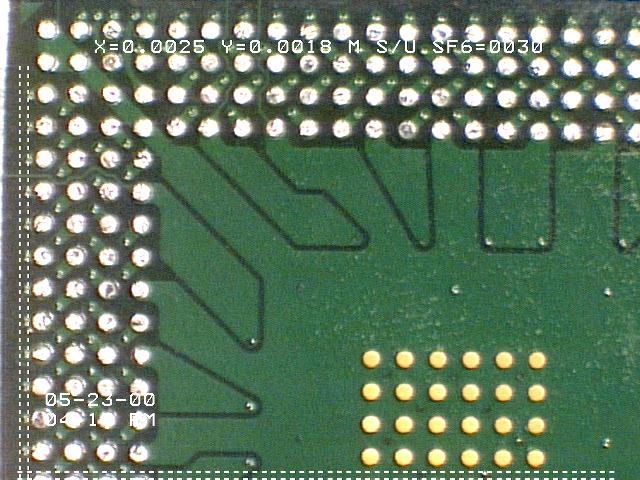

Use micro stencils for holding the balls and printing the paste or flux on to the device

Use a preform which is a single piece preform where the balls are captured in the preform in the pattern found on the device

One of the preform methods for BGA reballing involves the use of a preform made from a temperature-resistive polyimide and an adhesive backing that gets peeled off after reflow. The simplest, highest quality preform with the highest fiorst pass yield is the EZReball™ product.

The simple nature of the EZReball™ reballing process allows even the beginning repair technician to reliably and quickly replace balls on a BGA package. Alignment is simple with the edges of the preform being “squared up” with the sides of the package thereby eliminating the need to buy custom fixtures or frames. The adhesive is engineered such that the balls are firmly held in place until after reflow thereby reducing the problem of missing solder balls found in other techniques. After the device has been reflowed, the preform is simply peeled off, eliminating the time required in cleaning off residual paper used in other methods.

Contact BEST for an EZReball™ preform evaluation kit where you can see the BGA reballing process first hand.