The Importance of Maintaining PCB IPC standards

21st Jan 2021

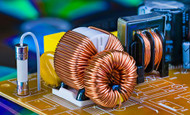

All manufacturers of safety and security equipment, aerospace components, automotive components, industrial equipment, consumer electronics, medical devices, and many other devices strictly stick by PCB IPC standards. What are IPC standards, and why are they so important? Printed circuit boards (PCBs) are used in countless manufacturing facilities across the world. Their quality needs to be consistent so that manufacturing processes can go smoothly. Trade associations like IPC set strict standards for manufacturing PCBs to ensure this consistency in quality.

Understanding IPC

Interconnecting and Packaging Electronic Circuits (IPC) is the most important trade association when it comes to electronic interconnection devices. Used across almost all major industries globally, this trade association creates strict standards for the assembly and safety of electronic equipment. This member-driven organization also trains professionals involved in the electronic interconnection industry and conducts extensive market research to create better policies and updated standards of quality every year.

All pillars of the international electronics industry, from OEMs (original equipment manufacturers) to PCB manufacturers, stand on the guidelines set by this 60+ year-old trade association. It’s an accredited standard-creating organization and publishes yearly standards that dictate pretty much every phase of all electronic product manufacturing cycles in the world.

Be it designing a product, assembling it, or packaging it – every manufacturing industry professional must abide by its 300+ active standards to be considered globally compliant. Project managers, soldering professionals, assembly experts, and other professionals involved in manufacturing processes need accreditation from IPC-licensed training centers to be considered employable in the current market.

The Importance of IPC Standards

Since PCBs are used in most electronic equipment, irrespective of the industry, it’s vital to ensure they’re manufactured safely and deliver consistent and high-quality performances. Electronic components and products that abide by PCB IPC standards are considered market-worthy, so all manufacturing companies adhere to them.

Since IPC standards have dictated the global manufacturing industries for over six decades, there’s an IPC standard for every manufacturing phase. Companies that use or manufacture PCBs must stick to these standards to guarantee high-quality and reliable performances. Companies that comply with IPC standards benefit in numerous ways. The main benefits include –

Lower Manufacturing Costs

IPC standards are designed to promote innovation and reduce the amount of time it takes for PCBs and other electronic components to be manufactured and enter the market cycle. So, companies that consistently stick to these standards massively reduce manufacturing costs. Since every professional working in these companies knows about IPC standards, there’s a lesser risk of delays or rework requirements.

Better Product Quality

Since IPC standards always aim to improve the quality of PCBs and electronic components/products in general, companies that abide by these standards create better and long-lasting products, which boosts their profitability in the market.

Product Consistency

If all components, equipment, devices, etc., are manufactured as per IPC standards, the consistency in product quality also improves. When companies work with IPC-certified PCB manufacturers, there’s no need to waste time inspecting these components as all parties involved in the manufacturing cycle (supplier, vendors, PCB manufacturers, regulators, etc.) know what to expect.