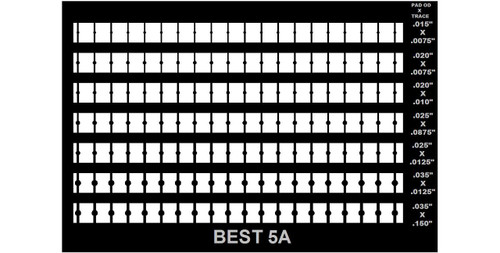

Circuit Frame for BGA Pads-Dry Film Method

It has a 6 month minimum shelf life and is date-coded on the circuit frame.Tin plated with dry film attached. The base metal is 1 oz copper with chemical etchant which results in a high bond strength to the PCB. The coating on the PCB side is an immersion bright tin coating.The backing film is a low stress epoxy film adhesive with a Tg at 60C. This minimizes the thermal stress on bonded parts during thermal cycling or shock testing from 55 to 150C. It is a clear 1mil (0.0254mm) in thickness material which helps to make for an aesthetically pleasing repair. It has a 6 month minimum shelf life and is date-coded on the circuit frame.

Specifications

Frame Size: 57 x 38 mm (2.25" x 1.50")

Material: Copper foil 0.036 mm (0.0014")-backside micro-etched for enhanced adhesion Adhesive

Backing: Phenolic film adhesive 0.0254 mm (0.001") thick.

Electrical Resistivity: Greater than 1014 ohm-cm

Dieletric Strength : 750 Volts/mil

Glass Transition Temperature: -60 C

Device push off strength: Greater than 2,000psi, or 13.8N/mm2

Peel Strength: Greater than 9lbs/in (1.61 kg/cm) post cure to FR-4

Hardness: 65 Type A

Cured density: 1.2 gm/cc

Thermal Conductivity: 1.2 BUT-in/hr-ft2-F

Linear Thermal Expansion: 110 ppm/C Max Continuous

Oper Temp: 150C

Bonding Time: 15 seconds Bonding Temperature: 200C

RoHS compliance: YES

Custom designs available in 5-10 business from BEST. No minimum order.

1 Review Hide Reviews Show Reviews

-

Nice product

The YouTube videos were really helpful to get the repairs on the pads done.