Are you in need of a flexible method for shielding nearby components during the PCB rework process? Do you find yourself looking for an effective heat shielding product which can be easily modified to protect a wide variety of components on your boards without enduring a long lead time?

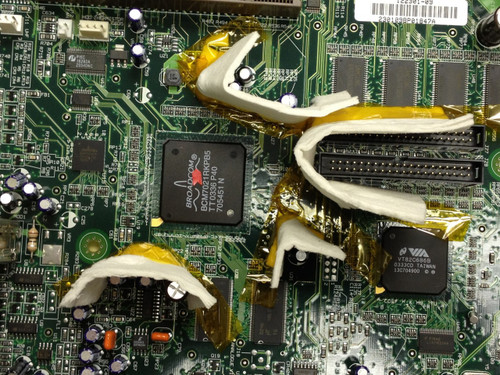

BEST’s HEATSHIELD™ is a flexible, effective heat shield material which is able to withstand very high temperatures shielding components such as temperature sensitive connectors, batteries, electrolytic capacitors in the area being reworked. Supplied in sheets 6 x 6" x 1/8", (2) per bag, this ceramic-based non-woven shielding material can protect electronic components during extended reflow profiles.

It is designed to protect adjacent IC components from secondary solder joint reflow due to nearby heat from the rework or assembly process. In addition, it is designed to be fit by you to fit all types of device shapes and sizes HEATSHIELD™ protects components against excessive heat that can compromise device reliability.

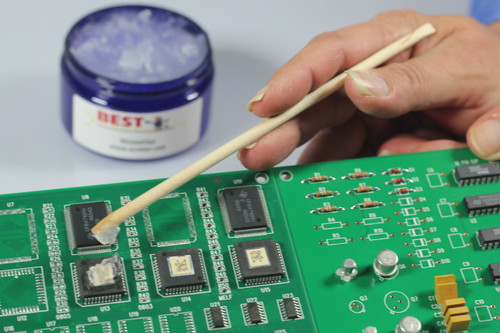

HEATSHIELD™ heat shielding material comes packaged with several sheets to every container. The shield material is configured to the shape you need by simply cutting the shield material to the size you need. It is affixed in and around those components needing protection with high temperature polyimide tape. By simply blanketing the area in and around the device to be protected and affixing it into position with high temperature-rated tape your components are protected. Coolshields™ are designed for 3-5 uses when subjected to direct rework temperature heat sources. Its pliable (1/8”- mm) walls can be used to place the shield material in to tight locations or to wedge it in to position so it does not move during processing.

Use HEATSHIELD(TM) to protect your components while enabling high yields. This shield material provides up to 60C temperature reduction for the adjacent component package body and up to 35°C temperature reduction for the protected component solder joints.