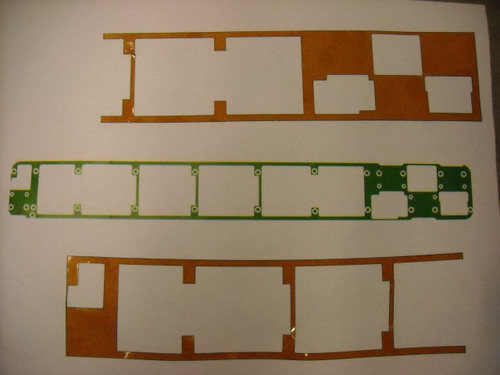

BEST Inc. provides custom polyimide shims and gaskets made from high temperature rated, electrically insulating, corrosion resistance, strong, wear resistant films. These shims fit a variety of applications in which there needs to be a heat barrier between two objects that can be accomplished with a flexible film either with or without an adhesive. BEST lasers can make these precision parts for prototypes as well as production quantities. BEST specializes in the fabrication of high end materials such as Kapton™ and Cirlex™ which can be produced in a wide variety of thicknesses from 2 mils up to 125 mils and are available with high temperature permanent adhesive backing.

There are several properties which make these custom Polyimide shims well-suited for medical, aerospace, defense, electronics and other performance-oriented industries.

- Strength- Polyimide, Kapton™ and Cirlex™ have strong mechanical properties and can act as a wear strip

- Flexibility-since the material is made in a variety of film thicknesses the material can be easily fit into tight areas or spaces requiring a seal

- Radiation resistance- these materials exhibit good resistance to radiation which is helpful in the medical, aerospace and defense market

- Temperature Resistance- These materials perform well in extremene environments with a temperature range from -452 F to +500F while showing good wear and mechanical strength properties in these extreme temperatures

- Electrically Insulating- These film are highly effective insulators and perform well as protection in motors, high voltage equipment, compressors and power generation equipment

- Little to No Outgassing- this property is well-suited for space applications

There are numerous industries where these material properties are well-suited. These custom polyimide shims are particularly well-suited in the aerospace industry. They are commonly used as washers, seals, motor mounts and vibration isolation barriers. If a camera mounted on a space craft needs to be protected from heat and vibration such shims are well-suited for these environments. Additional material properties of these film which are advantageous to the aerospace applications include chemical resistance to fluids such as gas and oil. Finally, the light weight property of the material makes it extremely advantageous for space flight. The medical industry values these films as they have very good sealing properties as well as being able to precisely laser machined for miniature footprint applications. Military and defense applications require the films to protect vehicle-mounted components which are placed in harsh environments. In addition, these shims are light in weight and protect against excessive heat and are non-conductive which make them well-suited for high voltage applications.

BEST can work with you your requirements for the film and the adhesive system that is right for your application. Not only that but we can consult with you on your mechanical requirements as we have been laser machining these materials for many years. It takes this experience to cut adhesive/protective film laminates. BEST is also ITAR registered which means we can be a trusted partner in your military and defense applications.

Send us your requirements today at info@solder.net in order to get the process for fabricating your polyimide shims started.

Stencils Unlimited will meet your increasing design requirements of ultra precision metal parts. If you need high quality, burr free precision metal parts, Stencils Unlimited is your answer. Whether you need a few prototypes or several thousand parts, we can handle your requirements quickly and more economically than die stamped and machined metal parts.

Advantages of Laser Cutting over conventional machining: No non-recurring engineering fees Design complexity has very little effect on the cost of tooling Perfect solution for prototype proofing and quick time to market projects Designers can tweak a part or try different designs quickly and at low cost Prototypes are produced using the same method as production parts Clean and Burr Free Edges Does not change the grain structure or hardness of the metal No Stress to metal

Thickness – 0.001” – 0.030”

Metals we can Cut:

- Stainless Steel

- Copper

- Brass

- Titanium

- Carbon Steel

- Spring Steel

- Alloy Steel

- Invar Metals

- Kovar Metals

- Others