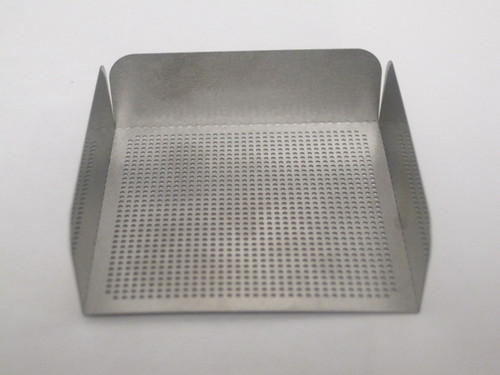

Miniature SMT Rework Stencils are laser cut solder paste stencils designed to replicate the initial manufacturing process albeit for a designated component or select area. These laser cut mini stencils can either have flaps (to prevent neighboring areas from getting solder splashed on them as well as to hold them) or not have flaps. They are well-suited for a robust rework process.Shipment is 24 business hours from approval of checkplot.

These rework stencils with integral flaps are specifically designed for manually printing solder paste onto printed circuit boards in select areas.

Mini stencils are laser cut stencils custom-made for your own printed circuit boards using your Gerber or CAD files. These mini solder paste stencils were specially designed for manual printing. Our SMT mini metal stencils will make your rework job easier.

Key features:

* High quality nickel-stainless PHD material (Much better release than std stainless stencils) means smoother aperture walls and cleaner release characteristics

* Clean Laser-Cut Apertures

* Excellent Print Performance

* We can provide guidance on the rework process since we are a rework services provider. We are not just a company cutting holes in to a piece of metal. We can also teach you on how to properly print using these mini SMT rework stencils.

See the study of the expected consistency of printing with mini metal stencils used in rework.

11 Reviews Hide Reviews Show Reviews

-

Fast and Accurate

Thanks for turning this around so quickly. Thanks Quinn

-

Simple transaction

There were a couple of back and forths but product was correct when it showed up.

-

Stencil Arrived One Day Later than I Expected

Stencil worked fine. I ended up having to slide another job in ahead of this one, but it worked out.

-

Fast Delivery

Fast delivery. Seamless process and order.

-

Fast and Correct

Needed a fast turnaround and I got it

-

Good transaction

Got stencil. Was what I ordered

-

Fast Ship

Got the stencil the next day. Thanks

-

Good stuff

Product came to me quickly

-

Thanks for the help

Chris worked with me to get the window paning on the tricky QFN done correctly