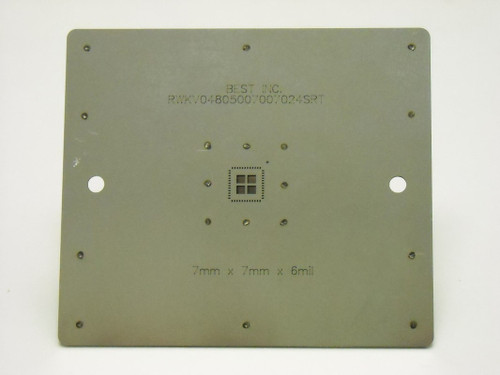

Component Printing Templates

Based on its long work on BGA rework and repair process and its in-house capability to produce metal stencils BEST can provide for you a timely, cost-effective solution for printing on to components for MOST rework systems.

Our templates for printing on to components allows you to print on the underside of components. This easy procedure is designed for use on BTCs (such as LGA and QFN package types), BGAs and CSPs. Many times it is used for small components and for board layouts where traditional stencil access is limited by the close proximity of adjacent components. (See another solution involving the “bumping” of parts here or the paste printing of locations using a highly flexible post-it type stencil here).

The typical process is part is placed in to the”pocket” of the stencil fixture. This pocket is designed for the part to fit reasonably snuggly on to the pocket while still being able to be extracted later. The fixture is “flipped” over whereby a stencil pattern is exposed. On this side solder paste is rolled via a micro squeegee across the bottom of the device. Proper stencil aperture engineering is required. The fixture is then aligned to the tooling holes for the VJT rework machines on the rework machine of choice and the pick tube “picks” the printed component form the fixture.

Unlike the machine manufacturers themselves there are (2) main reasons to pick BEST for this type of tooling. First of all BEST has lots of experience in reworking thousands of BGAs-so we can design the right tools for the job. Secondly, unlike the machine vendors, all of this work is done under one roof where we can control the quality, the costs and lead time.

Shipment is 3 business daysfrom approval of checkplot.

1 Review Hide Reviews Show Reviews

-

Know their stuff

They were able to quickly get me what I needed. Custom tooling worked out well